- Spare parts

- knives | blades

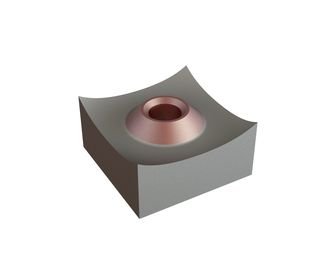

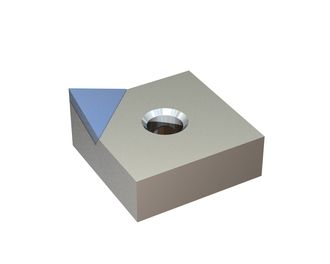

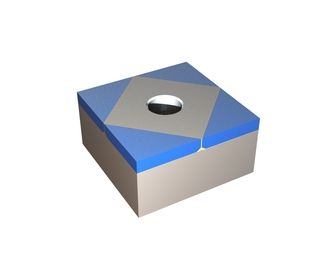

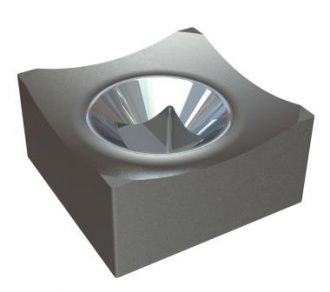

- shredder cutters | concave cutter

- counter knives | scrapers

- granulator rotor knives | fly knives

- granulator static knives | bed knives

- rotor shear spare parts

- baling press knives

- other blades | pelletising knives

- bolt-on cutting edges

- knife holders | knife pads

- sealing rings | wear rings

- screen baskets

- screen plates

- screen cassettes | screen holders

- screen accessories

- other spares | standard accessories

- electrics | hydraulics | pneumatics

- rotors

- transmission technology

- fastening material

- Manufacturers

- Vecoplan

- Lindner Recyclingtech

- Eldan Recycling

- Andritz Mewa

- Able

- Alpine Hosokawa

- Amni Maschinenbau

- ARP

- Artech

- Austro

- Bano Recycling

- BHS

- CM Shredders

- Condux

- Cumberland

- Doppstadt

- Dreher

- Eggersmann

- Erema

- Ermafa

- Folcieri

- Genox

- Getecha

- Görgens Mahltechnik

- Gross

- Guidetti

- Haas Recycling

- Hammel Recyclingtechnik

- Herbold Meckesheim

- HSM

- ISVE

- Kueny

- MACPRESSE

- Molinari Recycling

- Neue Herbold

- PAAL

- Pallmann

- Precimeca

- Previero

- Rapid Granulator

- Reto Redoma

- Rudnick & Enners

- STF

- Terex

- THM Recycling

- Tria

- Untha

- Vogelsang

- Wagner Shredder

- Wanner

- Weima

- Wipa

- Zato

- Zeno

- Zerma

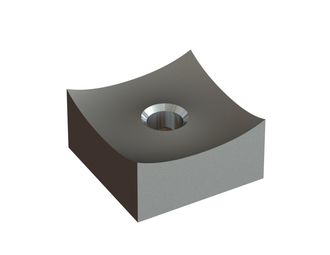

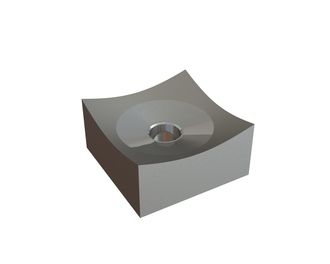

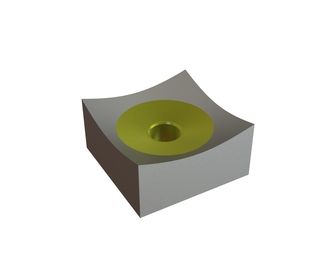

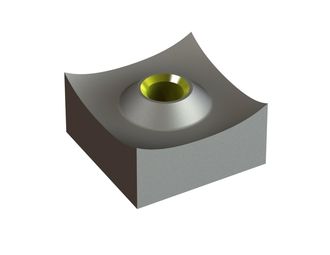

Cutter 40x40x20 Premium Line

Cutter HMVP0040-YK0 by CUTMETALL for crushing machines by Vecoplan.

Compatibility with machines:

- Lindner Antares

- Lindner Vega

- Vecoplan VAZ

- Vecoplan VAZ 1300

Cutting performance and durability:

This cutting tool can be adapted to the break down application, depending on the various materials and varying cutting geometry.

Due to the alloyed tool steel of the Y-option, it is approx. 5 % harder than the X-variant. This means that a longer operating time can be secured. In comparison, however, the cutter is more predisposed to impurities, which can lead to breakage more quickly.

Spare parts of this variation are hardened throughout, which means that this hardness remains persistent from the edge to the core. Due to that the wear is even in relation to its life cycle.

We underline that this version should not be armoured or welded on. This has a negative impact on the material structure of the cutter, which can subsequently lead to breakage and machine damage.

Fastening in the machine:

For attaching, the cutter has a drilling for M12 threads.

When installing the cutter, please ensure that it is only fitted to knife holders or knife crossbars with a flat contact surface in order to prevent breakage.

General characteristics:

The cutter is 0mm long, 0mm wide and 0mm high.

As this cutter belongs to our Premium Line, the spare part comes exclusively from German manufacturing.

Replacement and Wear Parts for Lindner Recyclingtech - Quality from CUTMETALL

At CUTMETALL, your specialist for high-quality replacement and wear parts, you will find a comprehensive selection of components for shredders, granulators, and pulverizers from the renowned brand Lindner Recyclingtech. Our expertise allows us to offer perfectly fitting, process-optimized products for every model of Lindner Recyclingtech. If you can't find your specific model on our list, do not hesitate to contact us. Our team is always ready to assist you quickly and competently.

About Lindner Recyclingtech

Founded in 1948, Lindner Recyclingtech has developed into a leading international manufacturer of machines for shredding and recycling waste materials. Based in Spittal, Austria, and with over 300 employees worldwide, Lindner serves customers in more than 70 countries. Thanks to an extensive product portfolio developed in-house, Lindner offers optimal recycling solutions for a variety of materials, including household waste, plastics, wood, paper, metal, and electronic scrap.

System Solutions from Lindner Recyclingtech

Lindner's shredding machines are specially designed to optimally prepare materials for recycling. Whether through multi-stage processes for the production of high-caloric substitute fuels or single-stage processes for medium-caloric variants - Lindner Recyclingtech offers efficient solutions for the processing of municipal and commercial waste. Specialized machines, such as the pre-shredder Lindner Jupiter or the fine-shredder Lindner Komet, guarantee high-quality end products.

CUTMETALL - Your Partner for Lindner Recyclingtech Replacement Parts

CUTMETALL offers not only precise and durable replacement and wear parts for Lindner Recyclingtech machines but also the expertise and consultation to maximize the productivity of your facilities. From rotors and blades to screen baskets and drive belts - every CUTMETALL product stands for quality and economy. Discover our customized solutions and learn how you can improve the service life and durability of your wear parts.

Why CUTMETALL?

- Wide Range: Whether you're looking for parts for Lindner Jupiter, Komet, Polaris, or other models, we have the right components for you.

- Flexible Measurement Service: If a needed part is not available, we offer you two options: We can measure the required spare part either directly on-site or you can send it to us for analysis.

- Precise In-House Lab Analysis: Regardless of the location of measurement, we conduct a comprehensive analysis in our laboratory. We determine not only the exact dimensions but also analyze the material of the spare part. This enables us to offer you the optimal variant for your plant.

- Long-Term Supply Security: By including the specially measured and analyzed part in our product range, we secure your current and future needs.

Trust CUTMETALL, your reliable partner for replacement and wear parts in the recycling and shredding industry. Contact us today to learn more about our products and services and how we can help you enhance the performance of your Lindner Recyclingtech equipment.

Replacement and Wear Parts for Vecoplan – Quality from CUTMETALL

At CUTMETALL, your specialist for high-quality replacement and wear parts, you will find an extensive selection of components for shredders, chippers, and other pulverizers from the renowned brand Vecoplan. Our expertise allows us to offer perfectly fitting, process-optimized products for every Vecoplan model. Should you not find your specific model in our list, do not hesitate to contact us. Our team is always ready to assist you quickly and competently.

About Vecoplan

Vecoplan AG is a globally operating company in the wood, waste, and recycling industry, active in the development, production, and distribution of machinery for raw material processing. Since its founding in 1969 in Bad Marienberg, Vecoplan has evolved into a leading manufacturer. With its headquarters and own technology center at the founding location, Vecoplan offers custom systems as well as proprietary technologies that set industry standards.

Technologies from Vecoplan

Vecoplan excels at making the recycling process efficient and economical through proper shredding of the input material. The product portfolio includes solutions for a wide range of materials, from wood and biomass to plastics and data carriers, significantly contributing to a successful recycling process.

CUTMETALL – Your Partner for Vecoplan Replacement Parts

CUTMETALL not only offers precise and durable replacement and wear parts for Vecoplan machines but also the expertise and consultation to maximize the productivity of your facilities. Discover our customized solutions and learn how you can improve the service life and durability of your wear parts.

Why CUTMETALL?

- Wide Range: Whether you're looking for parts for Vecoplan VAZ, VEZ, VIZ, Hurricane, or other models, we have the right components.

- Flexible Measurement Service: If a required part is not available, we offer you two options: We can measure the required replacement part either directly on-site, or you can send it to us for analysis.

- Precise In-House Lab Analysis: In our lab, we conduct a comprehensive analysis. We determine not only the exact dimensions but also analyze the material of the replacement part to offer you the optimal variant for your facility.

- Long-term Supply Security: By incorporating the specially measured and analyzed part into our product range, we secure your current and future needs.

Trust in CUTMETALL, your reliable partner for replacement and wear parts in the recycling and shredding industry. Contact us today to learn more about our products and services and how we can help you enhance the performance of your Vecoplan equipment.

Ready to optimize your Vecoplan equipment? Contact us now!